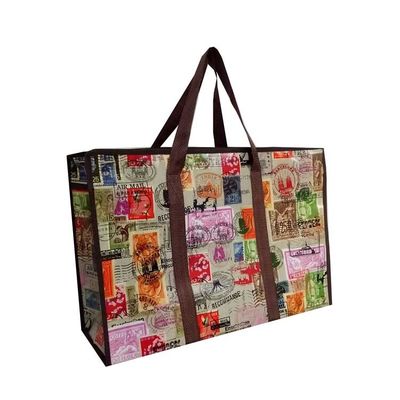

Eco-friendly PP Shopper Bag with 2cm Piping and Customized Service

Product Description:

PP Shopping Bag - Your Ultimate Shopping Companion

Are you tired of using flimsy and environmentally harmful plastic bags for your shopping needs? Look no further, because the PP Shopping Bag is here to save the day!

Product Overview

The PP Shopping Bag is a sturdy and durable carry bag made from high-quality polypropylene (PP) material. It is designed for all your shopping needs and is suitable for both men and women. With a customizable design and superior quality, this bag is perfect for promotional purposes and can be used as a fashion statement as well.

Service: OEM

Our PP Shopping Bag offers OEM (Original Equipment Manufacturer) service, which means we can customize the bag according to your specific needs and requirements. You can choose the color, design, size, and even add your logo or message to make it truly unique and representative of your brand.

Sample Time: 7 Days

We understand the importance of timely delivery, which is why we have a fast turnaround time of just 7 days for sample production. This allows you to see and test the product before placing a bulk order, ensuring your complete satisfaction.

Piping: 2cm

The PP Shopping Bag comes with a 2cm piping, which gives it a neat and structured look. The piping also adds to the bag's durability, making it capable of carrying heavy loads without any risk of tearing.

Applicable Gender: Neutral / Male And Female

Our shopping bag is designed to be gender-neutral and can be used by both men and women. It is suitable for all age groups and can be used for various purposes, such as grocery shopping, retail shopping, or even as a beach bag.

Industrial Use: Shopping

The primary purpose of the PP Shopping Bag is for shopping, making it an ideal choice for retail stores, supermarkets, and other shopping outlets. Its sturdy construction and customizable design make it a popular choice for promotional use as well.

Conclusion

In conclusion, the PP Shopping Bag is a versatile and eco-friendly product that serves as a practical and stylish solution to your shopping needs. With OEM service, fast sample production, and high-quality material, it is the perfect choice for your customized and promotional shopping bags. Order now and make a sustainable choice with the PP Shopping Bag!

Features:

- Product Name: Pp shopping bag

- Sample Time: 7 Days

- Color: CMYK

- Size: Small

- Usage: Shopping

- Piping: 2cm

- Key Features:

- No zip design

- Colored options available

- Customized with logo or design

Technical Parameters:

| Technical Parameters |

Description |

| Product Name |

Foldable PP Shopping Bag |

| Size |

Small |

| Service |

OEM |

| Sample Time |

7 Days |

| Gsm |

130gsm-190gsm |

| Payment |

TT |

| Color |

CMYK |

| Industrial Use |

Shopping |

| Waterproof |

Yes |

| Piping |

2cm |

| Usage |

Shopping |

Applications:

Pp shopping bag

The XIANGYUN brand is proud to present our pp shopping bag , a versatile and eco-friendly option for all your shopping needs. Made in CN and certified with ISO9001 , our bags are of the highest quality and meet all international standards.

With a minimum order quantity of 2000 PCS , our bags are perfect for both personal and retail use. And with a price range of $0.3--$0.8 , they are affordable for all budgets. Our bags are available in a variety of sizes and can hold up to 2cm of piping, making them suitable for all your shopping needs.

Our bags come in a vibrant CMYK color scheme, making them eye-catching and perfect for promotional purposes. And with a sturdy Gsm range of 130gsm-190gsm , they can hold up to heavy items without tearing.

We understand the importance of prompt delivery, which is why we guarantee a delivery time of 20 days after confirming the sample. We also offer flexible payment methods, including T/T .

Our bags are not only practical, but also customizable. As a part of our OEM service, we offer the option to print your own logo or design on the bag for a more personalized touch.

At XIANGYUN , we are dedicated to providing the best quality products and services to our customers. With a supply ability of 50000 PCS/DAY , we can meet all your bulk order needs. Join us in our efforts to reduce plastic waste and choose our pp shopping bags for your next shopping trip.

Customization:

Pp Shopping Bag Custom Service

Brand Name: XIANGYUN

Place of Origin: CN

Certification: ISO9001

Minimum Order Quantity: 2000 PCS

Price: $0.3--$0.8

Packaging Details: 12 PCS/BALE,120 PCS/PACKAGE

Delivery Time: 20 Days after confirming the sample

Payment Terms: T/T

Supply Ability: 50000 PCS/DAY

Service: OEM

Usage: Shopping

Load Weight: 20kgs

Payment: TT

Size: Small

Customize your own package pp shopping bag with XIANGYUN. Made with high quality materials and certified with ISO9001, our bags can hold up to 20kgs of weight. The minimum order quantity is 2000 PCS and our prices range from $0.3 to $0.8 per bag. Our packaging details include 12 PCS per bale and 120 PCS per package. With a supply ability of 50000 PCS per day, we guarantee timely delivery within 20 days after confirming the sample. Our service is OEM, so you can personalize your bags with your own design. Perfect for shopping, our no zip pp shopping bags are durable and reliable. Make your payment easily through T/T and choose the size that best suits your needs. Trust XIANGYUN for all your packaging needs.

Packing and Shipping:

Pp Shopping Bag Packaging and Shipping

Thank you for purchasing our Pp Shopping Bag! Here is some important information on its packaging and shipping:

Packaging

Our Pp Shopping Bag is carefully packaged to ensure its safe arrival to you. Each bag is individually wrapped in a protective plastic sleeve and then placed in a sturdy cardboard box. This packaging is designed to prevent any damage or tears to the bag during transport.

Shipping

We offer free standard shipping for all Pp Shopping Bag orders. Our standard shipping takes approximately 5-7 business days for delivery. If you need your bag sooner, we also offer expedited shipping options for an additional fee.

Once your order has been placed, you will receive a confirmation email with your tracking number. You can use this tracking number to monitor the status of your shipment and ensure a timely delivery.

Please note that we currently only ship within the United States. We apologize for any inconvenience this may cause.

Returns

If for any reason you are not satisfied with your Pp Shopping Bag, we offer a hassle-free return policy. Simply contact our customer service team within 14 days of receiving your bag and we will provide you with a return label and instructions for returning the product. Once we receive the bag in its original condition, we will issue a full refund.

Thank you again for choosing our Pp Shopping Bag. We hope you love it as much as we do!

FAQ

Factors affecting the size deviation of non-woven bags

The size deviation of non-woven bags may be caused by a variety of factors, including errors in the production process, quality problems of raw materials, and improper use by consumers. The following are the specific influencing factors:

Errors in the production process

Manufacturer’s technical level and equipment status

The size deviation of non-woven bags depends largely on the manufacturer's production process and technical level. If manufacturers adopt advanced production equipment and technology, they can effectively control dimensional deviations. On the contrary, if the manufacturer's technical level is low, or the equipment used is old, it may lead to increased dimensional deviation.

Manual accuracy

In the production process of non-woven bags, many manual operations are involved, such as cutting, sewing, etc. These links are highly dependent on manual skills and attention, so the accuracy of manual operations directly affects the dimensional deviation of the final product.

Raw material quality issues

Raw material specifications are inaccurate

The size deviation of non-woven bags may be related to the specifications of the raw materials. If the grammage or thickness of the raw material is inaccurate, it may result in deviations in the dimensions of the finished bag.

Mixture of raw materials

If raw materials of varying quality are used during the production process, or there are differences in raw materials from batch to batch, this may also lead to deviations in the dimensions of the finished bags.

Improper use by consumers

excessive use or wear and tear

Non-woven bags may experience wear and tear during long-term use, causing their dimensions to change. If consumers use the bag frequently or accidentally damage the bag during use, it may lead to size deviation.

Incorrect storage method

Non-woven bags may also change in size if they are stored incorrectly, such as if they are exposed to sunlight for extended periods of time or placed in a humid environment.

To sum up, there are various factors affecting the dimensional deviation of non-woven bags, among which errors in the production process and quality problems of raw materials are the main influencing factors. Consumers should also pay attention to correct storage and maintenance methods during use to extend the service life of the bag and maintain its dimensional accuracy.

International standards for sewing technology of non-woven bags

Regarding the international standards for non-woven bag sewing technology, we can draw the following conclusions:

First of all, there may not be a unified international standard for the sewing process standards of non-woven bags. In the search results, we found some requirements and standards regarding the sewing process of non-woven bags, but most of them come from domestic enterprises and internal regulations of the industry. Therefore, in this regard, we need to further study and explore whether there are universally binding international standards.

Secondly, we can learn some specific requirements for the sewing process of non-woven bags. For example, during the cutting process, the error should be controlled within a certain range; you need to backstitch once at the beginning of sewing and the lifting strap; during the wrapping process, pay attention to whether there are thread ends, whether the wrapping edge is broken, and whether the lifting strap is on Waiting. Although these requirements are not international standards, they still have certain reference value for understanding the sewing process of non-woven bags and improving product quality.

Finally, it should be noted that although there is currently no international standard for the sewing process of non-woven bags, in some countries and regions, there may be laws and regulations for the production and use of non-woven bags. Therefore, when producing and exporting non-woven bags, you also need to pay attention to the relevant policies and requirements of the target market to ensure that the products comply with local regulations and standards.

In short, we need further research and discussion on the international standard issue of non-woven bag sewing technology. In this process, we can refer to domestic enterprises and internal regulations of the industry to improve the quality of non-woven bags and meet the needs of different markets.

Quality control in the production of non-woven shopping bags

As an environmentally friendly product, quality control of non-woven shopping bags is very important. The following are the key points of quality control in the production of non-woven shopping bags:

1. Inspection of finished products

The quality control of non-woven shopping bags first needs to start with the inspection of finished products. This includes inspecting shopping bags for workmanship issues, size deviations, color issues, printing processes, etc. For example, there should be no obvious crooked bags, no seams or jumpers during sewing, uniform and fine stitching throughout, backstitching at the mouth, straight straps, smooth surface without stains, and a straight bag body. The size deviation of non-woven shopping bags cannot exceed 12.5cm. The center angle of the printing plate is correct, and the distance between top, bottom, left and right is appropriate. The color registration must be accurate, and the distance deviation cannot exceed 2.5cm. The load-bearing capacity of non-woven shopping bags, the load-bearing capacity of 80 grams of non-woven shopping bags should be greater than or equal to 10 kilograms, and the handle and edges should be firm. In addition, as for the color of non-woven shopping bags, there should be no deviation in the color of the fabric, and the color of the colored non-woven fabric should be bright. The printing process of non-woven shopping bags must be standard. No matter what printing method is used, the color coverage must be strong, the color of the pattern and text must be consistent, the overall angle must be clear and there is no obvious deviation, and it must be able to contrast with the cloth color. Non-woven shopping bags are environmentally friendly products. The printing must be non-toxic and odorless, and the materials must also be non-toxic and odorless.

2. Material selection

Choosing the right material is the basis for ensuring the quality of non-woven shopping bags. It is necessary to select a non-woven fabric with sufficient strength and durability, and take into account the weight and surface gloss of the fabric. The surface gloss of the fabric is helpful for later printing, while the harder fabric can increase the stiffness and practicality of the shopping bag.

3. Quality control during production

During the production process, a complete quality control system needs to be established to reduce the rate of defective products. This includes optimizing the production process to ensure the predictability of production; specifically raising and solving problems that may arise in the production of large quantities of goods; adjusting the human resources organization in a timely manner to ensure that responsibilities are implemented to specific positions; establishing a relatively fair set of The timing and piecework system, the performance appraisal system, reward workers for innovation, and encourage workers to exceed production; and establish a complete quality assurance system to reduce the rate of defective products and prevent rework losses caused by defective semi-finished products flowing into the next process to reduce costs.

4. Quality control during customization process

When customizing non-woven shopping bags, customers are required to provide design samples or logos and ensure production according to customer requirements. During the printing process, attention needs to be paid to color difference issues and copyright issues to ensure product quality and legality. In addition, material costs need to be reasonably controlled, including the cost of fabrics, handbags, edge strips and other materials.

To sum up, quality control in the production of non-woven shopping bags involves many aspects, and requires strict control from the selection of raw materials to the monitoring of the production process, to the testing of finished products and precautions during the customization process. .

Customized color difference control techniques for non-woven shopping bags

When customizing non-woven shopping bags, color difference control is an important link. Chromatic aberration issues can cause the final product to not look as expected, so it is crucial to master effective chromatic aberration control techniques. Here are the control tips:

1. Material selection and management

Non-woven fabric selection

Choose non-woven raw materials with stable quality, which can help reduce color differences caused by differences in raw materials.

Choose larger non-woven fabric manufacturers. These manufacturers usually have more stable sources of color masterbatch raw materials and can provide non-woven fabrics with more uniform colors.

Masterbatch management

Masterbatch is a key factor in determining the color of non-woven fabrics. Manufacturers should choose fixed masterbatch for production to avoid color differences caused by replacement of masterbatch.

For customers with special color requirements, you can choose to have the manufacturer customize the company's special color masterbatch, which can better control the color difference.

2. Color difference control during production

Printing process control

During the printing process, the same kind of ink should be used as much as possible to avoid mixing inks of different properties to avoid affecting the printing effect.

Pay attention to the storage conditions of the ink and avoid direct sunlight and extreme temperatures that may affect the properties of the ink.

During the printing process, the ink should be stirred regularly to prevent sticking, and the viscosity and ph value of the ink should be controlled to ensure printing quality.

Maintenance of printing equipment

Keep printing equipment in good condition, and reduce the impact of equipment on printing results by regularly maintaining and lubricating key parts.

During the printing process, a stable vehicle speed should be maintained, which helps to control the ink balance and reduce color difference.

3. Customer communication and sample confirmation

Confirmation of customized plan

Before starting production, customers should fully communicate with the manufacturer about the customization plan, including the required color, pattern and other information, to ensure that both parties have consistent expectations for the final product.

Sample confirmation

During the production process, customers can confirm the color and pattern in advance by making samples, so that color difference problems can be discovered and corrected in time.

Precautions

Since the color of non-woven fabrics depends on factors such as the ingredients of the masterbatch and temperature changes during the production process, color differences may occur in each batch of non-woven fabrics.

Even if the non-woven fabric is purchased from the same manufacturer, there may be slight color differences from the actual product due to reasons such as photography, light, display, etc.

Through the implementation of the above techniques, the color difference problem in the customization process of non-woven shopping bags can be controlled to a certain extent, ensuring the quality and beauty of the final product.

Solution to color difference problem of non-woven shopping bags

The color difference problem of non-woven shopping bags mainly comes from two aspects: one is the color difference of the raw materials, and the other is the color difference during the printing process. Here are solutions for both:

1. Raw material color difference problem

The raw material for making non-woven shopping bags is non-woven fabric, and the raw materials and masterbatch purchased by the non-woven fabric factory will be different each time, which may lead to color differences in the product. In order to solve this problem, manufacturers can store non-woven fabrics produced in the same batch of different colors that are often used by some large customers. Choosing non-woven fabrics produced with the same serial number can ensure that the color difference is within the minimum range. In addition, powerful non-woven environmentally friendly bag manufacturers have their own color cards corresponding to image colors. If the number of customized non-woven bags is large, you can find the manufacturer to customize special colors for your company.

2. Color difference problem during printing process

The occurrence of color difference during the printing process is mainly due to factors such as different ingredients each time, temperature changes during cloth production, etc., resulting in each batch of cloth being different. In order to solve this problem, manufacturers can strictly control the printing process and promptly notify the non-woven fabric manufacturer for replacement if a large color difference is found. In addition, you can use standard printed four-color computer color matching to choose larger non-woven environmentally friendly bag manufacturers. Such manufacturers have stable sources of color masterbatch raw materials, strict ingredients requirements, and high process requirements, so the quality of non-woven fabrics is higher. It can also ensure basic uniformity.

3. Customer-side solutions

For consumers, they can choose non-woven shopping bag manufacturers with good reputation and quality assurance. When choosing a manufacturer, you can ask to see their color cards and samples to understand their production processes and quality control measures. In addition, printing color accuracy can be ensured by providing standard international PANTONE color numbers.

4. Technical improvements

With the advancement of technology, the problem of color difference is expected to be alleviated. For example, printing accuracy and consistency can be improved by improving printing technology and equipment.

At the same time, color differences caused by factors such as temperature changes can also be reduced by optimizing ingredients and production processes.

To sum up, the solution to the color difference problem of non-woven shopping bags mainly involves raw material procurement, printing process control, customer selection and technical improvement. Through the implementation of these measures, the occurrence of color difference problems can be effectively reduced, and product quality and consumer satisfaction can be improved.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!